Table of Contents

Introduction

In today’s data-driven and highly competitive business environment, smart organizations use data analytics capabilities and advanced analytics methodologies in Supply Chain Management to gain real-time insights into business data to stay on top of their game.

Using data analytics in different business fields enables organizations to keep track of their performance and identify areas for improvements.

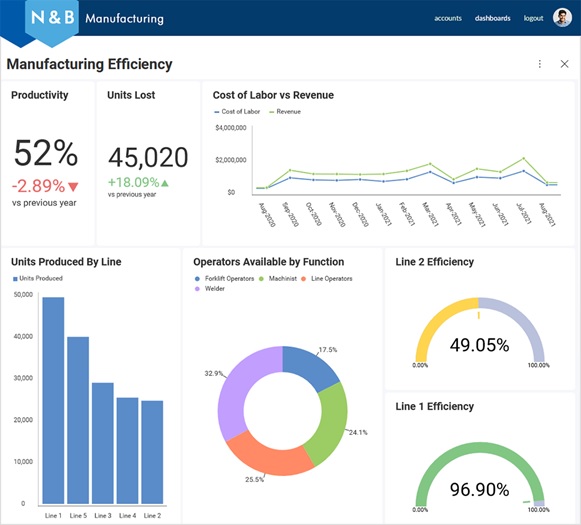

One business field in which data analytics has become crucial for decision-making and survival is manufacturing. Manufacturers use data analytics tools and techniques to monitor their machines, orders and inventory, manage warehouse, sales and CRM operations, and predict future demand or risks by spotting trends and patterns throughout the supply chain processes.

Supply chains generate tons of data from orders, warehouses, transportation management, and more. When using data analytics in the supply chain, manufacturers can make sense of all that data and forecast future demand accurately to help the business plan their manufacturing accordingly.

Supply chain analytics helps organizations across various industries make smarter business decisions about their operations that can ultimately affect quality, delivery, customer experience, and of course, profitability.

Here are a few real-life examples of how data analytics is used in supply chain management:

Data Analytics in Supply Chain Demand Forecasting

The use of data analytics in supply chain demand forecasting is all about the science of predictive analytics which uses current and historical data patterns to estimate the likelihood of future events and outcomes. In the manufacturing context that means that by applying predictive analytics techniques to your supply chain analytics process, you can combine the data from all of your previous orders with real-time market analysis to find out what customers want and are likely to buy. This creates a better and more accurate demand forecast than any human supply chain planners can. Ultimately, successful demand forecasting helps you avoid overspending on procurement and keep costs down while still meeting customer demands.

Data Analytics in Supply Chain Inventory/Warehouse Optimization

Inventory and warehouse optimization are two other areas in which supply chain analytics is commonly used. Inventory optimization is the process of setting inventory levels to balance demand and supply uncertainty while keeping costs down and maximizing customer service. Warehouse optimization, on the other hand, is the process in which the use of time, space, and resources in a warehouse is made more efficient through automation and planning.

Many organizations still use spreadsheets for inventory/warehouse optimization, yet this is a highly inefficient and time-consuming process. Managing all this data and analyzing it intelligently with the help of data analytics tools and techniques allows you to easily reduce inventory and potential service risks and determine optimal inventory levels and locations for certain products. It helps model inventory policies smarter, optimize schedules for warehouse employees, order picking activities, and much, much more.

Data Analytics in Supply Chain Distribution and Logistics

Furthermore, data analytics can help you optimize your supply chain by accounting for expected delays and allowing you to avoid them. That way, you can speed up your shipping processes, and ensure faster fulfillment and customer satisfaction. With an analytics solution in place, you can monitor your distribution performance in real-time and identify which distributors are delivering orders on time, keep track of the numbers of shipments, routes of delivery, picking and packing orders, etc.

Final Thoughts

Supply chain analytics provides comprehensive visibility into an organization’s supply chain operations, allowing them to uncover opportunities for improvements and a better understanding of customers’ needs. It is a key tool in achieving real success, increasing operational efficiency, and growing your revenue. The better an organization performs supply chain analytics, the more successful it would be.

![Data Analytics Used in Supply Chain Management [2025]](https://www.computertechreviews.com/wp-content/uploads/2022/11/Data-Analytics-Used-in-Supply-Chain-Management-1200x675.webp)