Table of Contents

Introduction

In the fiercely competitive landscape of hardware performance, heat dissipation has become a critical bottleneck limiting performance release. Engineers invest immense effort in designing complex heat pipe arrays and intricate fin topologies. However, the efficacy of all these designs hinges on one simple yet stringent premise: the heat sink base must achieve near-perfect microscopic contact with the chip surface. So, why do processes like casting or CNC milling struggle to achieve this perfect contact? The root cause lies in the differences in surface texture and residual stress inherent to their machining principles—microscopic defects that directly translate into high interfacial thermal resistance.

This article will use engineering principles and factual data to demonstrate the irreplaceable advantages of Aluminum CNC Turning in creating ultra-flat surfaces, preserving the material’s excellent thermal conductivity, and achieving cost-effective, precision mass manufacturing. Let’s now delve into these three core dimensions to uncover the truth behind the data and facts.

The First Dimension: The Cornerstone of Heat Transfer – Why Does Turning Create a “Colder” Surface?

The efficiency of heat transfer begins at every microscopic point of contact between two surfaces. Interfacial thermal resistance is the primary adversary between the chip and the heat sink.

Surface Morphology: The Microscopic Battlefield Determining Thermal Resistance

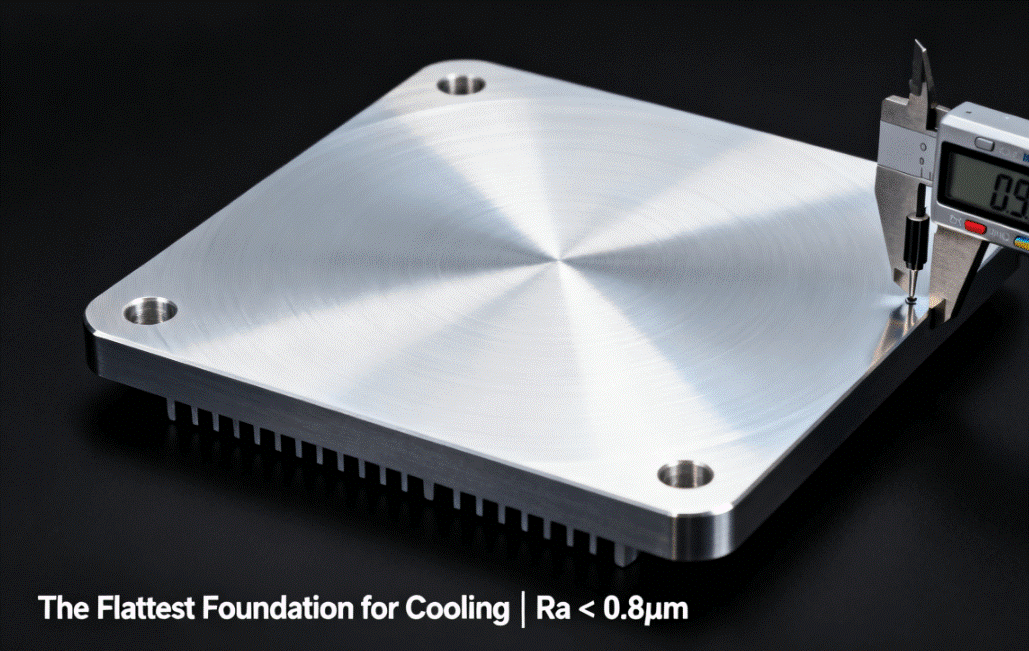

- Continuous Cutting vs. Interrupted Cutting:The tool in Aluminum CNC Turning performs a continuous, unidirectional cutting motion. This action generates uniform, coherent microscopic textures, allowing surface roughness (Ra value) to be consistently controlled at an excellent level of 0.4-0.8μm. In contrast, the tool in CNC milling engages in interrupted cutting, which can cause slight vibrations and chatter marks, leading to irregular surface textures with greater peak-to-valley variations.

- Fewer Air Voids:A smoother, more uniform surface means that when combined with the chip surface using thermal paste, it can significantly displace and reduce air gaps (air has very low thermal conductivity). This allows heat to transfer more smoothly across the interface.

- Lower Thermal Stress Impact:The cutting forces in the turning process are relatively low and stable. Coupled with the excellent thermal conductivity of the material itself (such as CNC 6061 aluminum), this significantly reduces the impact of machining-generated heat on the material’s microstructure. As noted by the authoritative ASM International in its discussion on the impact of surface engineering on thermal contact conductance, the flatness and consistency of the surface are among the most critical factors for reducing interfacial thermal resistance.

Guardian of Material Integrity

In Heat sink CNC machining, controlling the thermal input of the process is crucial. The efficient chip evacuation and controlled cutting parameters in turning ensure that the heat generated during machining is quickly removed, preventing microstructural changes in the base material due to overheating, thereby laying a solid physical foundation for cooling performance.

The Second Dimension: The Limits of Geometric Precision – How to Achieve “Absolute Flatness” and “Perfect Concentricity”?

For high-end heat sinks, a smooth surface alone is not enough; macroscopic geometric precision is another lifeline for ensuring even heat extraction.

The heat sink base must possess extremely high flatness to ensure full-area, uniform contact with the chip’s integrated heat spreader (IHS), avoiding localized hot spots caused by a “teetering effect.” Simultaneously, for designs using a press-fit process (where fins are pressed into base grooves) or requiring precise alignment with a cold plate housing, the concentricity and perpendicularity of the base relative to related structures are paramount.

Aluminum CNC Turning naturally excels in this aspect. The rotational accuracy of a turning machine’s spindle is extremely high (often within 1μm), and the workpiece itself rotates, resulting in simple and deterministic tool paths. This machining characteristic gives it a natural advantage when producing rotationally symmetrical parts or those requiring extreme flatness, such as aluminium cnc turning parts. For high-end heat sinks, a base flatness of less than 0.05mm is a basic requirement, while precision turning can consistently achieve 0.01mm or even higher levels. This pursuit of absolute flatness is the core value of professional Precision parts machining services.

The Third Dimension: From Lab to Mass Production – How to Ensure Perfection from the First Unit to the Ten-Thousandth?

As critical components, the batch-to-batch consistency and reliability of high-end hardware heat sinks are directly tied to brand reputation. The core competitiveness of an aluminum cnc machining service is precisely reflected in the perfect replication from prototype to mass production.

Standardization and Process Control

Mature aluminum cnc machining services utilize standardized tooling, rigorously validated and optimized machining parameters (such as speed, feed, depth of cut), and fully automated production lines to ensure that the dimensions and surface quality of every part in mass production are highly consistent with the prototype. This stability is the foundation for successfully translating lab data into market-ready products.

Quality Control Systems Beyond Hardware

Precision manufacturers capable of serving industries with extreme reliability demands, such as automotive (IATF 16949) or aerospace (AS9100D), have production process control systems (like SPC – Statistical Process Control) that fully meet the stringent consistency requirements of top-tier CNC machining computer hardware. This means every batch of heat sink bases you receive undergoes the same rigorous quality inspection.

Traceability and Continuous Improvement

A robust system also implies complete production traceability. Any minor deviation can be quickly identified and corrected, enabling continuous process optimization and ensuring that the “ten-thousandth unit” is potentially even better than the “first unit.”

Material and Process: Why is 6061 Aluminum the Mainstream Choice?

The advantages of a process must be combined with suitable materials to maximize their effect. Among the various CNC aluminum options, CNC 6061 aluminum has become the mainstream material for heat sinks due to its optimal balance of multiple key properties.

First, its thermal conductivity is approximately 167 W/m·K. While not as high as pure aluminum or copper, it effectively meets the needs of most high-performance cooling scenarios.

Second, 6061 aluminum alloy offers good strength, sufficient to ensure the structural integrity of the heat sink fins and base, while achieving a perfect balance between weight (density) and cost. Furthermore, it has excellent machinability, making the Aluminum CNC Turning process efficient with low tool wear. Finally, 6061 aluminum responds well to anodizing, providing both an aesthetically pleasing, durable protective surface finish and the ability to create brand identity through coloring.

In comparison, the 5052 series has poorer thermal conductivity, while the 7075 series, though stronger, is more difficult to machine and more expensive. Therefore, for manufacturing high-performance custom cnc aluminum cooling components, 6061 is undoubtedly the “optimal solution” considering overall performance.

Beyond Heat Sinks: How Precision Turning Defines the Internal Aesthetics and Structure of Hardware

The influence of Aluminum CNC Turning extends far beyond heat sinks. It is a foundational technology for building high-performance, high-reliability hardware ecosystems.

For example, monoblock water cooling head housings require extremely high internal wall finish and chamber concentricity to ensure hydraulic efficiency; precision bearing sleeves for quiet and stable fan operation demand exceptional roundness and dimensional accuracy; load-bearing guide pillars in server chassis and special connectors requiring extremely high fitting accuracy directly impact the stability of the entire system. The presence of precision turning technology is ubiquitous in Precision chassis manufacturing and Aluminum enclosure machining.

These applications collectively demonstrate the critical role of this process in defining the internal aesthetics and structural strength of hardware. This widespread need for precision is where professional CNC Turning capabilities shine. Therefore, partnering with a supplier possessing comprehensive engineering capabilities and a strict quality control system is crucial. This is also why service providers like JS Precision are highly regarded in the high-end manufacturing sector.

Conclusion

In summary, the fact that over 90% of high-end heat sinks opt for Aluminum CNC Turning is no coincidence. It is the inevitable result of the combined effects of thermodynamic principles, precision engineering requirements, and the economics of mass manufacturing. From microscopic surface texture to macroscopic geometric precision, and on to batch consistency, it lays a solid and reliable foundation for the ultimate release of hardware performance.

When designing next-generation hardware or seeking manufacturing solutions for critical components, you should no longer view CNC machining as a black box. Deeply understanding and specifying the correct process is the key step to ensuring your design intent is 100% translated into product performance. Consult a professional precision manufacturing service provider immediately to obtain a process feasibility analysis for your project.

Author Bio

The author of this article is a senior industry analyst deeply engaged in the intersection of advanced manufacturing technology and computer hardware, with years of experience in precision engineering research. Their focus is on ultra-precision machining processes, hybrid additive-subtractive manufacturing, and other cutting-edge directions, committed to promoting the industrial application of innovative manufacturing technologies in the high-end hardware sector.

FAQs

Q: What is the most fundamental difference between aluminum CNC turning and milling in heat sink manufacturing?

A: The most fundamental difference lies in the tool motion and the resulting surface characteristics. Turning is suitable for rotationally symmetrical parts, producing more uniform and coherent microscopic textures. It is more efficient at achieving ultra-high flatness and concentricity, making it the preferred choice for critical surfaces like the heat sink base.

Q: Why aren’t heat sinks made from pure copper? Isn’t copper better for thermal conductivity when CNC machined?

A: Copper does have better thermal conductivity. However, it is denser (heavier), more expensive, and more difficult to machine. Aluminum alloy (like 6061) offers the best balance of “thermal conductivity, weight, strength, cost, and machinability.” By maximizing its thermal potential through precision turning, it becomes the optimal solution considering overall cost-effectiveness.

Q: How can you judge the quality of a heat sink base machined by CNC turning?

A: The most straightforward industrial standards are measuring its surface roughness (Ra value) and flatness. A lower Ra value (e.g., <0.8μm) and higher flatness (e.g., <0.03mm) indicate a flatter surface, lower interfacial thermal resistance, and a better foundation for cooling performance.

Q: Is this process only suitable for mass production? Can it be used for small-batch prototypes?

A: Absolutely. Modern precision machining service providers (especially those with certifications like ISO 9001) typically offer rapid prototyping services. Using CNC turning for prototypes allows you to obtain parts with performance and precision identical to mass-produced units, which is crucial for performance validation.

Q: Besides heat sinks, what are other typical applications of Aluminum CNC Turning in computer hardware?