If you’ve ever used an electronic gadget, you have interacted with a PCB. It’s what enables your phone, laptops, and yes, even electric guitars to do the things they do.

Table of Contents

Definition of a PCB

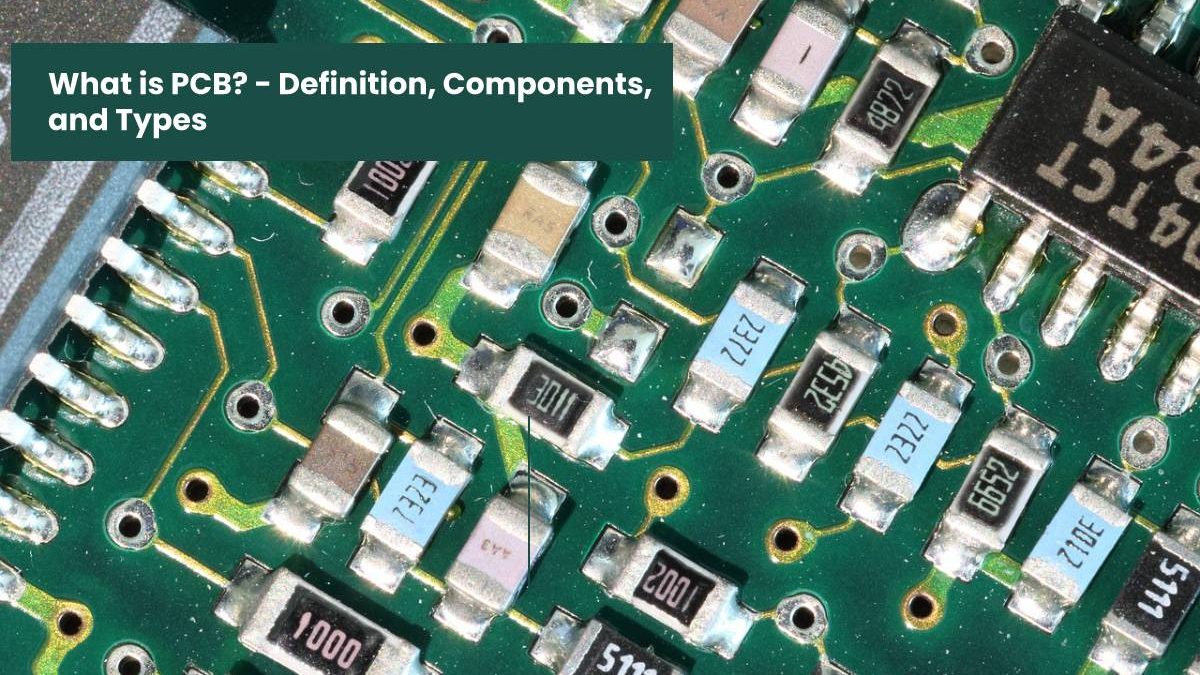

PCB or printed circuit boards are so ubiquitous that people tend to overlook them despite their crucial role in our highly digitized society. In a nutshell, PCB is a board that has lines and pads where electrical power and signals pass through – acting as the major functional centers of most electronics in our world today. That’s why getting your PC wet is a sure way of ruining your computer because it damages the PCB.

Layers of a PCB

PCBs have evolved throughout the years – going from one layer to today’s multi-layered PCBs present in your smartphone. Common PCBs include at least one substrate – the thin board that components are attached to – which today is commonly fiberglass or FR4. Other manufacturers use phenolics or glass as substrates, too.

The next layer is the copper-tin foil laminated in heat and adhesive. Then you have the solder mask on top of it – the green layer people usually recognize – and lastly, the white silkscreen layer.

Components of a PCB

There are a lot of things that go into even the simplest PCB. Each component performs some mathematical operation between voltage and current and does so over a specific range of conditions. Some common and key components of a PCB include transistors to amplify charge, resistors to control electric voltage and capacitors to harbor the charge. Others include inductors and diodes to store or stop the charge and switches to regulate them. Modern PCBs also have LEDs or light-emitting diodes which only allow the current to flow in one direction and batteries to provide direct voltage.

Different Types of PCBs

There are numerous types of PCBs, which are often categorized based on the number of layers, frequencies, and substrates. Altium details how different types of PCBs require a variety of design rules depending on their capabilities. Some require more layers or components while others like those used in sensors are designed to handle high-frequency signals like RF, microwave or millimeter-wave frequencies.

Single-Sided PCBs only use one substrate and are layered with one copper coating, a protective solder mask, and a silkscreen coat. As they are much simpler to manufacture and costs less, they are used for volume production and power simple circuits. Double-Sided PCBs have two metal layers connected either through through-hole technology or surface mount technology. These are the most common PCBs in the gadgets we use today such as smartphones, laptops and amplifiers etc. And to ensure your laptop’s PCB temperature is healthy you can even take a peep with a CPU Temp Monitor tool right now.

There are also multi-layer PCBs which use insulators to connect more layers – offering more design flexibility to engineers. These PCBs play an important role in high-speed circuits used in more complex computers.

There are also rigid, flexible, and hybrid PCBs which are categorized based on the flexibility of materials used for the substrate. While rigid PCBs are more common as they offer more advantages in arranging the components, flexible PCBs are used in more extreme environments where temperature and density matters.

Conclusion

As mentioned above, High-Frequency PCBs are used in communications and microwave technologies. In more extreme environments, engineers use aluminum backed PCBs to help in thermal control and heat dissipation.

PCBs today are getting smaller, lighter, and more powerful than ever. In fact, TechCrunch notes that startups like Tempo Automation are working to accelerate new ones from prototypes to volume production. Others work on new materials that are more heat resistant and resilient.

So, the next time you use any electronic gadget, remember it’s PCBs that power them.